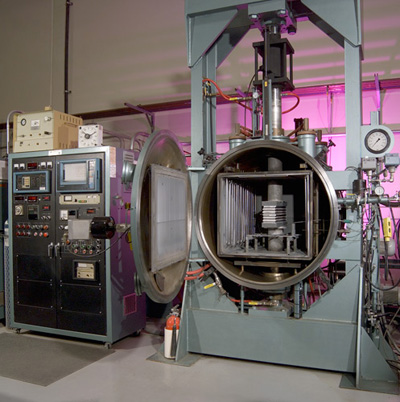

VACUUM INDUSTRIES SERIES 3600, MODEL 4236, 120 TON VACUUM HOT PRESS FURNACE WITH A 26"W X 26"D X 22"H ALL MOLYBDENUM HOT ZONE

The system is capable of temperatures up to 1,700°C in vacuum conditions of 10-6 Torr or better. The system has demonstrated MIL-SPEC temperature uniformity better than: +/-10°F as demonstrated by full quarterly survey testing in accordance with AMS 2750 and also includes gas manifolding and controls to run partial pressures of hydrogen or any desired inert gas. For diffusion bonding purposes, a hydraulic loading ram assembly is capable of furnishing dynamic loads of up to 120 tons.

The system routinely runs production loads of up to 60,000 LBF using 5-inch OD graphite ram tooling. The system is configured with a cryotrapped Varian VHS-10 diffusion pump stack, and has only been used with low vapor pressure braze al1oys to keep the "all-moly" hot zone "titanium clean".

An alternate graphite hot zone for use with high vapor pressure processes containing elements such as cadmium, copper, silver, zinc, or lead, etc. is also available for this system when needed.

The system routinely runs production loads of up to 60,000 LBF using 5-inch OD graphite ram tooling. The system is configured with a cryotrapped Varian VHS-10 diffusion pump stack, and has only been used with low vapor pressure braze al1oys to keep the "all-moly" hot zone "titanium clean".

An alternate graphite hot zone for use with high vapor pressure processes containing elements such as cadmium, copper, silver, zinc, or lead, etc. is also available for this system when needed.