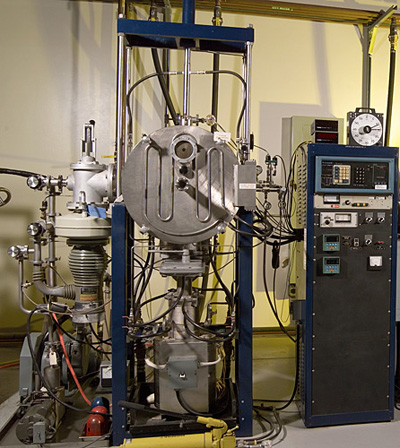

REFRAC SYSTEMS CUSTOM BUILT, 10 TON VACUUM HOT PRESS/VACUUM INDUCTION MELTING FURNACE WITH A 5"W X 6"H X 8"D TUNGSTEN ELEMENT GRAPHITE HOT ZONE

This system also has induction power feedthroughs within the 22" ID x 20" deep vacuum vessel and a 5.5" ID x 10" heated length vacuum casting (VIM) retort. The VIM retort includes a microprocessor controlled mold preheat capability, with an independent large gas volume vacuum pumping system, and a separate mold quench cooling system.

The system can also be easily configured to perform powder atomization or rapid solidification studies. Currently, the resistance hot zone system is limited to the melting point of the thermocouple insulators (alumina), using about 10% of the available resistance power supply. The upper temperature limitation using the induction heat power supply is well above 3,500°C.

The system can also be easily configured to perform powder atomization or rapid solidification studies. Currently, the resistance hot zone system is limited to the melting point of the thermocouple insulators (alumina), using about 10% of the available resistance power supply. The upper temperature limitation using the induction heat power supply is well above 3,500°C.